Pressure decay leak testing is one of the most widely used methods on manufacturing production lines. It is preferred because the process is straightforward, cost-effective compared to techniques like helium testing, and relatively easy to automate.

How Pressure Decay Leak Testing Works

In a typical pressure decay test, the component or part under inspection is filled with pressurized air. Once the desired air pressure level is reached, the part is isolated from the air supply. After isolation, a short stabilization period is allowed to ensure consistent conditions.

During the testing phase, sensors or transducers monitor the pressure inside the component. Any drop in pressure indicates the presence of a leak. The difference between the initial pressure and the final pressure measurement reveals the leakage rate.

If the pressure remains stable over the set time, the part is considered leak-free. On the other hand, a measurable pressure loss confirms that the part has a defect, ensuring that faulty components are identified before reaching the end user.

Advantages of Pressure Decay Leak Testing

1. High Accuracy

Pressure decay leak testing is known for its sensitivity and precision. The method can detect even the smallest leaks or micro-defects that may compromise the performance, safety, or durability of a component. This high level of accuracy makes it suitable for critical industries where reliability cannot be compromised, such as medical devices, automotive systems, and aerospace components.

2. Wide Range of Applications

One of the greatest strengths of this method is its adaptability across multiple industries. From packaging and consumer products to heavy machinery and industrial components, pressure decay testing can be applied to a wide variety of parts. Its effectiveness in identifying leaks in both small and large components makes it a universal choice for quality control.

3. Cost-Effectiveness

Compared with alternative leak detection methods such as helium or tracer gas, pressure decay testing is more economical. Since it relies on air as the testing medium, it minimizes consumable costs and becomes especially cost-efficient for large-scale production environments or industries handling high volumes of components.

4. Versatility in Testing Conditions

This method is flexible enough to be adapted to both positive pressure and negative pressure (vacuum) testing. Whether a component requires validation under pressurized conditions or vacuum environments, pressure decay testing can be configured to meet the specific needs of the application. This versatility ensures broader use in diverse manufacturing and inspection scenarios.

5. Non-Destructive and Reliable

Another advantage is that the test does not damage the product being tested. Components remain intact and can continue through the production process once they pass the inspection. This non-destructive nature adds to its value, especially in industries where material conservation and reusability are important.

6. Easy Automation and Integration

Pressure decay testing can be seamlessly integrated into automated production lines, making it highly suitable for modern manufacturing. Automation not only improves consistency and repeatability but also reduces labor costs and speeds up testing throughput.

7. Compliance with Industry Standards

As industries grow more regulated, ensuring compliance with leak testing requirements is essential. Pressure decay methods align well with global quality and safety standards, helping manufacturers avoid penalties, product recalls, or market rejections.

Applications of Pressure Decay Leak Testing

Consumer Electronics

Used for smartphones, smartwatches, wireless speakers, cameras, drones, and sensors.

Ensures resistance to dust, water, and environmental exposure, improving durability.

e-Mobility

Applied to fuel cells, bipolar plates, battery packs, and mobile energy systems.

Helps guarantee safety, performance, and long service life of energy storage and mobility solutions.

Automotive Industry

Commonly used for air conditioning systems, brake systems, fuel systems, cylinders, cooling circuits, gearboxes, and cameras.

Prevents failures that may affect vehicle safety and efficiency.

Household Appliances

Suitable for HVAC systems, refrigerators, kitchen ranges, faucets, coffee makers, and cooling coils.

Ensures proper sealing, energy efficiency, and longer operational life.

Medical Industry

Essential for blister packs, blood bags, syringes, IV bags, drip chambers, endoscopes, and sterile vials.

Maintains sterility, prevents contamination, and ensures patient safety.

Packaging Industry

Applied to plastic bottles, caps, cosmetic containers, food packaging, ink cartridges, and medical packaging.

Guarantees airtight sealing, product freshness, and extended shelf life.

Why Pressure Decay Testing is Widely Used

Product Safety – Detects leaks that could cause failures, contamination, or safety risks.

Regulatory Compliance – Helps meet strict international standards across industries.

Extended Shelf Life – Critical for medical and food packaging to maintain freshness and sterility.

Customer Satisfaction – Reduces consumer complaints, returns, and warranty claims.

Cost Efficiency – Minimizes waste, rework, and recalls by identifying leaks early.

Non-Destructive – Does not damage tested parts, allowing products to remain in use if they pass inspection.

Why Choose Pressure Decay Leak Testing Solutions

Extensive Industry Experience

With decades of development and application history, pressure decay leak testing has been proven effective across thousands of production environments worldwide. This wealth of experience ensures that the method is reliable, adaptable, and optimized for diverse industrial needs.

Advanced Technology and High Sensitivity

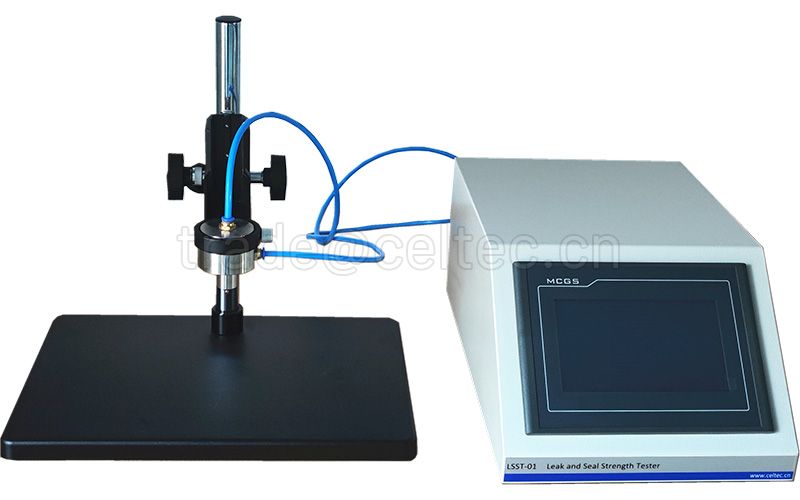

Modern pressure decay testing systems use cutting-edge sensors and fast-response instruments that deliver rapid cycle times and exceptional accuracy. These advancements make production lines more efficient and ensure components consistently meet even the strictest quality and safety standards.

If you want to learn more about how pressure decay leak testing can be applied to your specific industry, improve product quality, or optimize production efficiency, consult with a leak testing specialist. Expert guidance can help you select the right system, configure testing parameters, and ensure your operation is fully compliant with industry regulations.