Pressure Decay Leak Test

Como é efectuado um ensaio de decaimento da pressão?

To begin the Pressure Decay leak test, the test part [TP] is attached to the test port. The tester then pressurizes the part with pressure [+P] to the desired test pressure set by the pressure regulator [R1] during the Fill step by opening valves [V1] and [V2].

Upon completion of the Fill step, pressure is trapped inside the part as [V2] closes. After a slight delay, [V1] closes allowing the line between [V1] and [V2] to vent to atmosphere through [V1] allowing any leakage through [V2] to cause the tester to see this leakage and fail all tests. The extra valve allows for a fail-safe configuration.

Trapped pressure inside the test circuit is held through the Stabilize step and then measured by the testers pressure sensor [PS] during the Test step.

If the part exceeds the programmed leak tolerance (pressure drop over time or quantified leak rate), the tester’s display indicates the reason for the test failure and displays the pressure loss or leak rate in user defined units of measure.

Upon completion of the Test step, pressure trapped in the part is vented to atmosphere through [V1] by opening [V2] during the Vent step, and the tester is ready for the next test.

Pressure Decay Test Systems

Pressure decay leak testing is the most commonly used method. Its simplicity makes it easy to automate and to integrate into production/assembly processes.

In simple terms, the pressure decay test fills a pressure vessel with air until it reaches its target pressure, cuts the air source to isolate the pressure, and measures the decay (loss) of that pressure over a set period of time; a pressure loss greater than a predetermined setting indicates a leak. The sensitivity and accuracy of the pressure decay measurement is a function of the test part’s size and the test time. Most tests can be performed rather quickly, with highly accurate results, but the larger the part, the longer the cycle time that is required to achieve an accurate test result.

What is a Pressure Decay Leak Test?

Pressure decay is one of the most widely used

Here’s how it works:

Connect your part to a leak tester with a fitting or fixture. During the FILL stage your part is pressurized.

Once the desired test pressure specified by the manufacturer has been reached and the fill time has ended, the SETTLE stage commences accommodating for part stretching or flexing.

Once the part has settled and the settle time has ended, the pressure decay TEST initiates. During the test stage a pressure sensor will measure any drop in pressure.

After the pressure decay test the remaining pressure in the system is vented to atmosphere during the VENT stage.

If the pressure decay of your part remains within your specification then your part PASSES and a green light illuminates. If the pressure decay of your part falls below your lower limit, then your part FAILS and the red light illuminates.

The advantage of this type of testing is that it is accurate up to the 5th decimal place or 0.00001 PSI allowing for fast test cycles.

Sample Applications:

Catheters

IV Set

Tubing

Needleless Injection

Bag

Implantable Device

Infusion Set

Metering Device

Sensors/Indicators

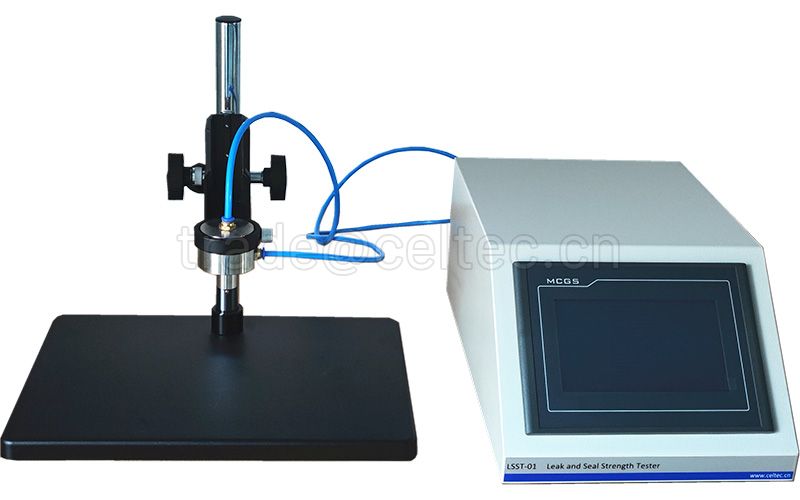

Suggested Leak Testers For Pressure Decay

Pressure decay is one of the most widely used methods of leak testing in manufacturing and is ideal for a sealed component with an access port. In this test, a product is attached to a leak tester and filled with air. Once pressurized, the air source is valved off and the pressure is allowed to settle. During the test any decrease in air pressure over time signifies a leak. If the part does not leak/decay past its predetermined reject value, it is a good part. The sensitivity of this test is dependent upon the product’s size and the time interval of the test. Larger objects require a longer cycle time to reach a high enough sensitivity for a quality test. Smaller objects with small internal volumes will require very low cycle time, allowing a high throughput of production.The advantage of this type of testing is that it is accurate up to the 5th decimal place or 0.00001 PSI allowing for fast test cycles.

If you would like more information about this product, please feel free to contact us.