Understanding Melt Flow Rate (MFR) in Plastic Processing

Measuring Melt Flow in Polymers

The Melt Flow Rate (MFR) determines the amount of polymer extruded through a specific orifice within a set timeframe. Accurate measurement is crucial for efficient polymer processing.

Standard Methods for Melt Flow Testing

ASTM D1238 – Standard Test Method for Melt Flow Rates of Thermoplastics

ISO 1133 – Determination of Melt Mass Flow Rate (MFR) and Melt Volume Flow Rate (MVR)

Impact of Melt Flow on Plastic Processing

Inconsistent MFR can negatively impact productivity and product quality. High melt flow can lead to flashing and equipment damage, while low melt flow may cause incomplete part filling, increasing reject rates.

Factors Influencing Melt Flow

Polymer characteristics, such as molecular chain structure, significantly affect melt flow properties.

Key Considerations:

High Molecular Weight = Lower MFR, indicating stronger bonds and higher viscosity.

Low Molecular Weight = Higher MFR, signifying easier flow due to increased polymer backbone mobility.

Selecting Melt Flow for Various Processes

Blow Molding: Use resins with low MFR (0.2 to 0.8).

Extrusion: Select resins with an MFR around 1.

Injection Molding: Higher MFR resins (10 to 30) are preferable.

Choosing the Right Purge Compound for Melt Flow Variations

Transitioning between resins can be challenging. Asaclean offers purge compounds tailored to different processes, resin types, and MFR requirements.

Consultation for Optimal Purge Compound Selection

If you’ve faced issues with purging due to resin compatibility concerns, consulting a technical sales representative can help select the best purge compound.

Melt Flow Index Testing – Why is it Important for Plastics?

Plastic’s popularity comes from its flexibility and recyclability. The Melt Flow Index (MFI) helps determine which plastic is suitable for specific applications.

Why Test the Properties of Molten Plastic?

Viscosity is crucial for determining plastic suitability. Manufacturers must test the raw material’s behavior under processing conditions to ensure optimal results.

How to Check the Melt Flow Index?

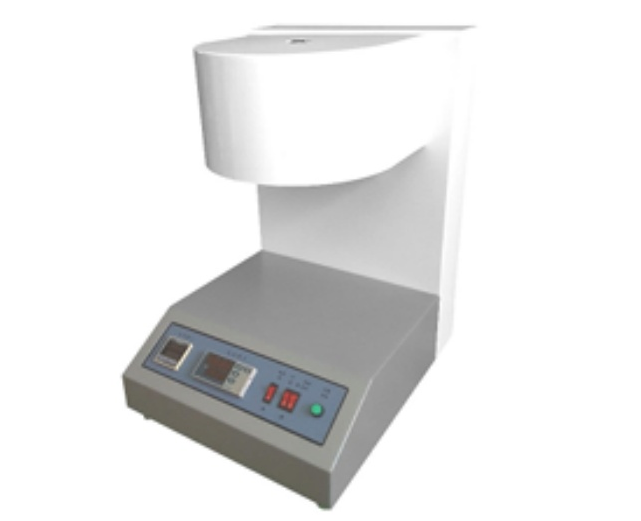

A lab testing instrument heats plastic granules up to 400°C, measuring the extruded material over 10 minutes. The weight of extruded plastic determines the MFI.

What Is a Melt Flow Index Tester and Why Use It?

그리고 MFI Tester is a key instrument in the plastics industry for measuring polymer resistance to flow.

How Does an MFI Tester Work?

A polymer specimen is placed in a heated barrel. A piston applies force, extruding the material through a die, measuring the flow rate.

Benefits of MFI Testing

Helps verify in-house material quality.

Assists in supplier material comparisons.

Provides insights into polymer behavior in different processing techniques.

결론

Understanding Melt Flow Rate (MFR) is essential for plastic processing. Proper testing ensures product quality and helps optimize manufacturing processes.

Need Expert Consultation?

If you require assistance in selecting the right testing equipment or purge compounds, contact us for expert guidance.

we can offer high quality products, competitive price and best customer service. Our destination is “You come here with difficulty and we give you a smile to take away” for Melt Flow Index Tester Price,Horizontal Tensile Tester,전동 캡 토크 테스터,Torque Testing Machine,Wholesale Film Heat Seal Tester,Internal Bond Tester,Pendulum Hammer Striking Tester,Puncture Testing Machine,Top Load Tester,Friction and Peel Tester,Film Heat Seal Tester

이 제품에 대한 자세한 정보가 필요하시면 언제든지 문의해 주세요. 다른 인기 제품을 추천해 주세요: Pendulum Hammer Striking Tester, Laboratory Hot Tack Tester, plastic film testing, Laboratory Heat Seal Tester, 젤보 플렉스 테스터 가격, 젤보 플렉스 테스터 제조업체, heat seal tester price, 핫 택 테스터 가격, Hot Tack Tester wholesaler, 젤보 플렉스 테스터 제조업체, 젤보 플렉스 테스터 공급업체, Gelbo Flex Tester wholesaler, 젤보 플렉스 테스터 서비스, 젤보 플렉스 테스터 솔루션, 의료용 포장 테스터 솔루션, 전동 캡 토크 테스터 제조업체, 전동 캡 토크 테스터 공급 업체, 전동 캡 토크 테스터 서비스