Leak testing is crucial for industries like plastic, food and beverage, and dairy industry to preserve the integrity of products within the package. It is an important part of their quality control process. Even minute physical breaches in a package such as leaks or cracks can spoil quality of products making it unfit for use. Therefore, it is important to use high quality leak detection instruments that can detect leaks in timely manner and ensure container quality is not compromised. As important as leak testing is, it is vital to conduct leak tests without causing damages to the product or packages. Manufacturers currently rely on non-destructive leak detection techniques that ensure effective testing of packages without spoiling its usefulness.

Testing empty containers for leaks and defects is the most effective way to ensure product quality. However, being able to identify such defects efficiently is essential for bottle manufacturers. A pressure decay leak test is an ideal way to identify defect in empty containers.

While vacuum decay testing is popular, it is not ideal for empty bottles. Vacuum decay can often cause empty bottles to collapse during the test.

Pressure decay testing is a great alternative that allows defects to be quickly identified. All while maintaining bottle integrity throughout the test. In this blog, we will discuss what you need to know about detecting container leaks with pressure decay testing.

Overview of pressure decay leak testing

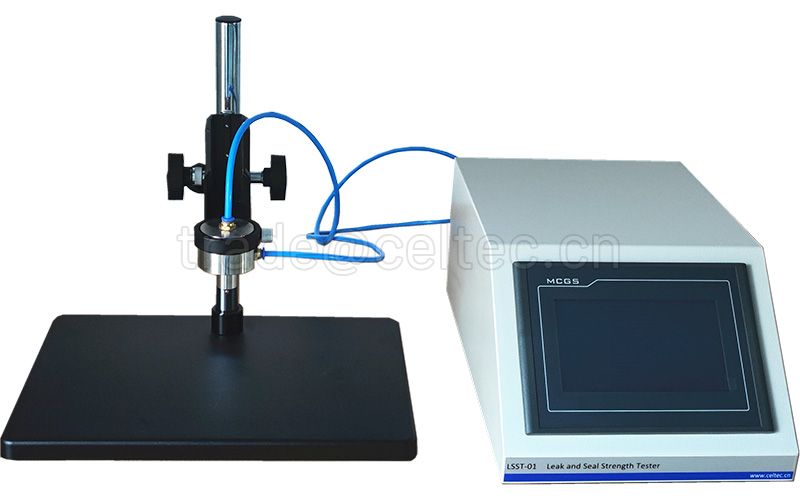

A Pressure decay leak test involves evaluating the drop in pressure on a transducer during a leak test. Under this method, the component under test is pressurized (filled with air until it reaches a set pressure), then isolated from the supply pressure. Using a pressure sensor, the pressure within the part is monitored. The pressure drops as the air leaks out. The leak rate can then be calculated based on change in pressure over a certain period.

The biggest advantage of pressure decay test is that it is sensitive to very small leaks. This makes it an ideal choice for leak testing in industries such as automotive components, castings, food and beverage containers. Not just that, compared to other methods, pressure decay leak testing is simplest of the leak test methodologies and is therefore generally the least expensive to implement. Hence this method is well suited for high-volume industries that require quick accurate tests within their facility such as beverage containers for milk, juices and other beverage products.

Pressure Decay Leak Test: Why It Is Ideal for Empty Container Leak Testing

While vacuum decay is a popular leak testing option, it is not ideal for empty bottles. Pressure decay is a great alternative to allow defects to be identified quickly, all while maintaining bottle integrity.

Pressure Decay Leak Test vs. Vacuum Decay

Are you testing filled containers or empty containers? If you are testing empty containers that are not required to have a vacuum seal, then a pressure decay leak test is the most efficient method. Pressure decay is also beneficial in applications where the lack of container stability allows the possibility of an empty container to collapse during testing.

If you’re testing a filled container or one that requires a vacuum seal, then a vacuum decay test may be your best solution. Vacuum decay testing is a non-destructive test that detects leaks in nonporous, rigid or flexible packages. This method ensures that packaging that contains items such as food or beverage are safe from possible container leakage after being filled and sealed.

The Benefits of Choosing on-Line Leak Testing

First and foremost, leak testing ensures that products will not leak out of the container. And that oxygen, moisture, and other contaminants will not get in. In turn, this helps maintain product quality and integrity.

Not only that, but our leak detection system tests each bottle as part of the manufacturing process. This provides much better results compared to random sampling, which does not guarantee defect detection.

You also enjoy better monitoring of the blow molding process. Issues with leaks can be an early warning sign that one or more of your pieces of manufacturing equipment may be faulty or may require maintenance and servicing.

Together, these benefits help you protect your inventory and prevent costly returns of faulty products.

How Does a Pressure Decay Leak Test Work?

Pressure decay leak test consists of 3 steps:

Fill – The bottle is filled to the desired peak pressure, which is controlled by an electronic regulator.

T1 – The percentage drop in pressure is measured a certain period of time. After it reaches its peak to measure its performance against a pre-set limit.

T2 – The percentage drop from T1 pressure is measured against another pre-set limit, ensuring the stability of the bottle.

Not only does pressure decay testing measure peak pressure, but also changes in pressure over time. This could indicate a small leak that may not be caught with 1-step pressure decay testing.

The three steps of the pressure decay testing process.

“Rules of Thumb” For Pressure Decay Testing

There are a few things you need to keep in mind when pressure decay testing:

Sensitivity increases as you increase test time. The longer you test a bottle, the more time the system has available to detect pressure drops.

Hole size detection depends on the sensitivity of the unit. Other pressure decay 테스터|、플라스틱 테스트 공장s can miss holes up to 1mm (larger than a paper clip).

Some pressure drop is normal even in good bottles. As containers may stretch under pressure slightly while the air stabilizes after pressurization.

It takes longer to detect leaks in large bottles and containers than smaller units, due to the increased volume of the product.

It is important to try to control temperature variations on the line as much as possible. This will help ensure proper consistency with pressure decay testing equipment.

Leak & Pressure Testing: Air Decay Leak Testing Methods

For these solutions, standard leak testing measurement instruments are incorporated to find a change in air pressure or air flow on the components being tested.

When comparing leak testing methods, air decay testing offers the following:

Overpressure air decay leak testing (above 0 bar)

The lowest cost solution

Simple to understand results data

Direct value results

Direct calibration

Temperature-dependent process (alternative test method is vacuum testing)

Best when used when component under test is stable

Overpressure leak testing is suitable for the following component and environment applications:

Volumes up to 3 litres

Stable temperature parts

Read more about our High Pressure (Over 6 bar) and Low pressure (0-6 bar) leak testing machines.

Vacuum air decay leak testing (below 0 bar)

Offers more robust leak testing

Greater integrity of data

Limits temperature dependency effects

Assists sealing loading

Reduced stabilisation time

Often a faster throughput

Indirect leak calculation

Offers complex fault detection

Vacuum leak testing is suitable for the following component and environment applications:

Volumes up to 5 litres

Parts subject to moderate temperature variation

Read more about our Vacuum Leak Testing machines.